This article will furnish you with an outline of the most generally utilized cannabis and hemp extraction equipment and methodology used to remove THC, CBD, and other essential cannabinoids.

Because of the extraction strategies illustrated, we will cover most of the cannabis extraction equipment and procedures expected to separate, distill and refine CBD, THC, CBN, CBG, and other prominent types of cannabinoids and their derivatives.

Here you will learn about the cannabis extraction equipment and systems required for the fundamental phases of the cannabis derivatives to create the most demanded hemp and cannabis available in the market today.

What is Cannabis Oil Extraction?

The chemicals that bind to special cannabinoid receptors in the body, called the Endocannabinoid system, are known as Cannabinoids. They can be inside the body (endocannabinoids), extracted from plants (phytocannabinoids), or made artificially.

There are 120+ different cannabinoids in the cannabis plant. The two popularly known are THC and CBD. Other cannabinoids that have a high demand in the market are CBG, CBN, THCV, and THCA, which are very helpful in treating various ailments and diseases.

Extraction is a nonexclusive term utilized generally to envelop a few phases of the cannabis and hemp oil extraction, refining, and filtration measure. Furthermore, for most finished results, extraction is only one of the initial phases in the excursion of changing biomass (crude cannabis plant material) into a high-quality product that is promptly bioavailable and fit to be offered to customers.

Extracting herbal oils from plants is an old technique that dates back thousands of years. Oil is extracted from various plants for different reasons: therapeutic oils, fragrant oils, food flavorings, and fragrance-based treatment.

However, regarding cannabis or hemp extraction, the basics are the same but procedures are different. For instance, when separating lavender oil, you are looking for a molecule that produces an aroma. Similarly, when separating cannabis or hemp oils, we choose explicit atoms from over 120+ distinctive cannabinoids.

Biomass: Starting with the Right Stuff

Everything harvested or collected from the cannabis or hemp plant is called biomass. It includes the flower, fan leaves, stalks, seeds, trim, everything, and anything cut from the living plant. Instead of separating the high-cannabinoid parts of the plant, they homogenize (blend) the entire plant. Due to the presence of the cannabis or hemp flower, the biomass is higher in cannabinoids.

Extraction Methods, Equipment, and Systems

1. Equipment for Ethanol Extraction

Ethanol is one of the most popular solvents and is the safest method for extracting cannabinoids from hemp and cannabis.

Ethanol can likewise be recuperated and reused for numerous extraction patterns to make the extraction cycle economical and expand return on investment.

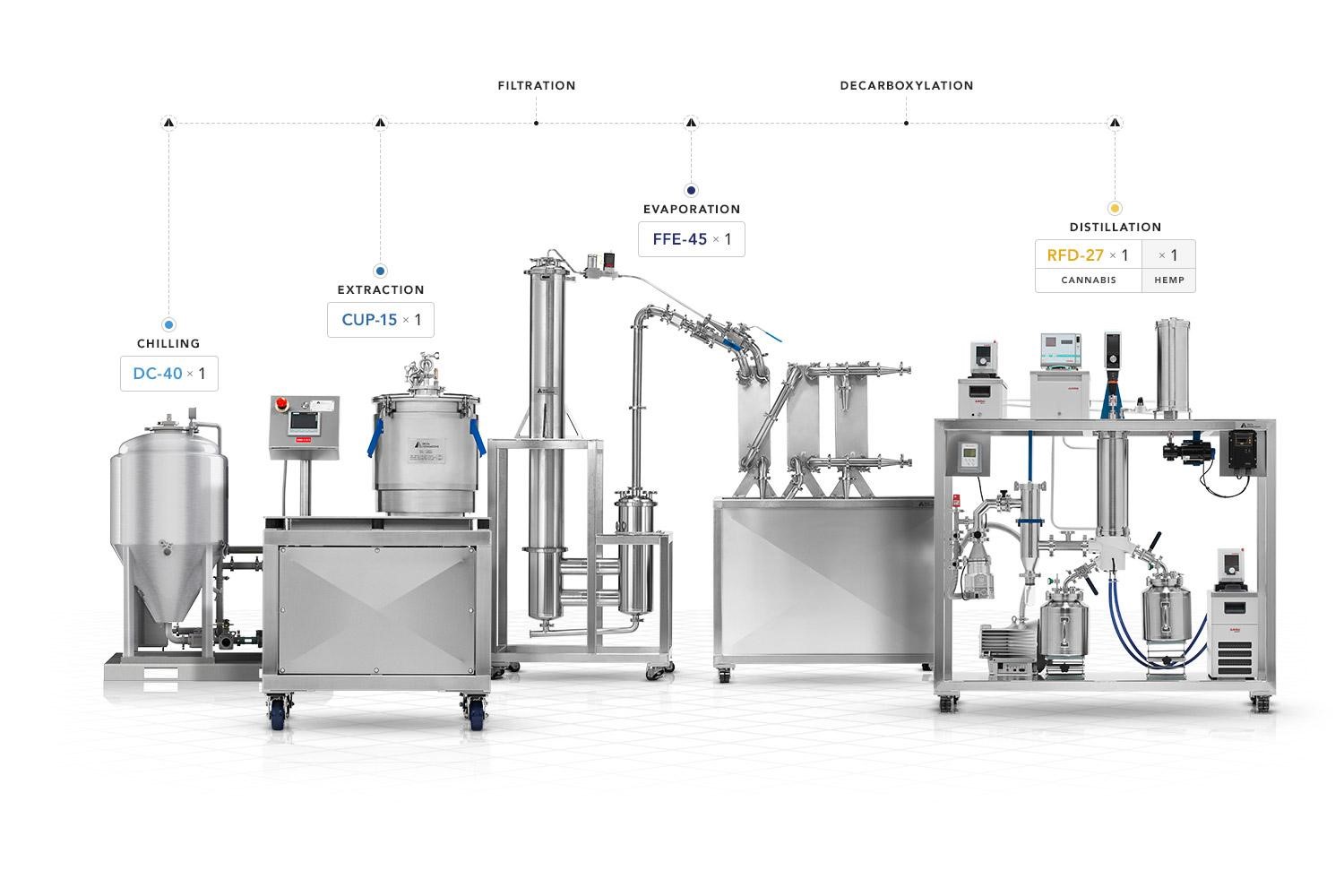

The ethanol extraction process follows the following procedure:

Chilling: Pre-chill ethanol dissolvable utilizing the DC-40 Direct Chiller to as low as – 40℃ to diminish the requirement for post-extraction steps.

Extraction: Soak and foment the biomass in chilled ethanol solvent to remove cannabinoid compounds through CUP Series shut circle mechanical centrifugation.

Filtration: Remove suspended particulates and adsorbents through Ethanol Extraction Filtration Skid

Evaporation: Remove ethanol from unrefined petroleum utilizing the Falling Film Evaporator (FFE).

Decarboxylation: Heating raw ‘acidic’ variants of the cannabinoid atoms (like THCA, CBDA, and CBGA) to release the carboxyl molecules like CO2 and convert them to their more easily consumed versions (like THC, CBD, and CBG).

Refining: Separating the cleansed THC, CBD, CBG, or other beneficial atoms from the raw petroleum using Rolled Film Distillation (RFD).

2. CO2 (Carbon Dioxide) Extraction Equipment

Like ethanol, CO2 is perhaps the most famous solvent used to separate cannabinoids and terpenes from hemp and cannabis. The interaction of CO2 extraction utilizes compressed carbon dioxide CO2 as a dissolvable to extract CBD, THC, terpenes, and other minor cannabinoids from cannabis and hemp. One of the primary advantages of CO2 is that it yields unadulterated cannabinoid subsidiaries. In addition, CO2 is viewed as an exceedingly protected method for extraction because, as a solvent, it is non-unstable and leaves no residual or synthetic substances.

Equipment: The extraction of CO2 is conducted by a “closed-loop extractor.” It is an extractor vessel that is completely sealed off from the outside atmosphere such that the CO2 solvent never comes in contact with the air. Instead, the CO2 solvent is coiled through the closed-loop framework traveling through the hemp or cannabis biomass repeatedly to separate however many cannabinoids and terpenes as could reasonably be expected. There are three chambers within a “closed-loop” system:

- The primary chamber contains compressed, liquid CO2 ;

- The subsequent section contains hemp or cannabis biomass;

- The third chamber isolates the following extricated item.

Industry professionals choose Closed-loop CO2 extraction systems because they are more economical, proficient, safer, and equipped for delivering more excellent end-products.

3. Hydrocarbon (Butane, Hexene, etc.) Extraction Equipment

Like CO2 extraction, hydrocarbon extraction is directed by a closed-loop extractor—a completely sealed vessel. The hydrocarbon solvent (propane, butane, or hexene) moves through the closed-loop system and through hemp or cannabis biomass to extract as many cannabinoids and terpenes as possible.

The hydrocarbon extraction measure regularly begins with releasing cold liquid butane from the dissolvable tank into a chosen biomass segment. This activity breaks down the terpenes and cannabinoids (THC, CBD, and other minor cannabinoids) alongside plant waxes and lipids into the solvent. The concentrated cannabinoid tincture is then gathered in a vessel where the picked hydrocarbon solvent is off-gassed off with the help of heat and vacuum. This last gassing off or cleansing the solvent might be acted in numerous ways, relying upon your final product. For instance, if you’re making shatter, the cannabinoid-rich concentrate is fanned out daintily, and afterward, it is put in a vacuum oven for more than 36-48 hours. In any case, in case you’re delivering wax or budder, the initial concentrate is whipped to produce any excess hydrocarbons. The remaining solvent is then gathered to reuse in the following group.

4. Cold Pressed Oil Extraction Equipment

When practicing cold pressing cannabis or hemp oil, the process is similar to cold pressing olive oil. The plant material is chilled, put under tremendous pressure, and is squeezed to extract cannabinoid and terpene-rich oil from the biomass pre-cooled cannabis or hemp plant matter (blossoms, leaves, seeds, or potentially stems).

A cold press machine commonly has a basin or cylinder into which a huge pivoting screw component is embedded. The extractor pivots the screw, and plant material is squashed, compelling oil to be removed out of the trichomes of the biomass. The oil is then gathered as it escapes out through little openings in the bottom of the basin.

Being solvent-free, the subsequent cannabis or hemp oil is perceived by connoisseur segments of the cannabis market to be cleaner, more natural, and have an original flavor of the first plant material—ideal for the individuals who love the “dank” taste and smell of cannabis.

However, there are some restrictions that people must know before purchasing Equipment to save time, money, and regulatory hassles.

Knowing these restrictions in advance of purchasing equipment can save you time, money, and regulatory hassles. Not just because laws and guidelines change between nations, from state-to-state and from one area to another, yet in addition since working out your office to be consistent can be perhaps the costliest steps in planning and building your lab past your initial equipment investment.