The marijuana species generates about 120 distinct compounds, resins, and antioxidants, making it one of the most complicated plants. Various techniques can be used to address each one of the types. Depending on the relative derivative, the volume you’re operating at, and the grade of the end-product, the process can change.

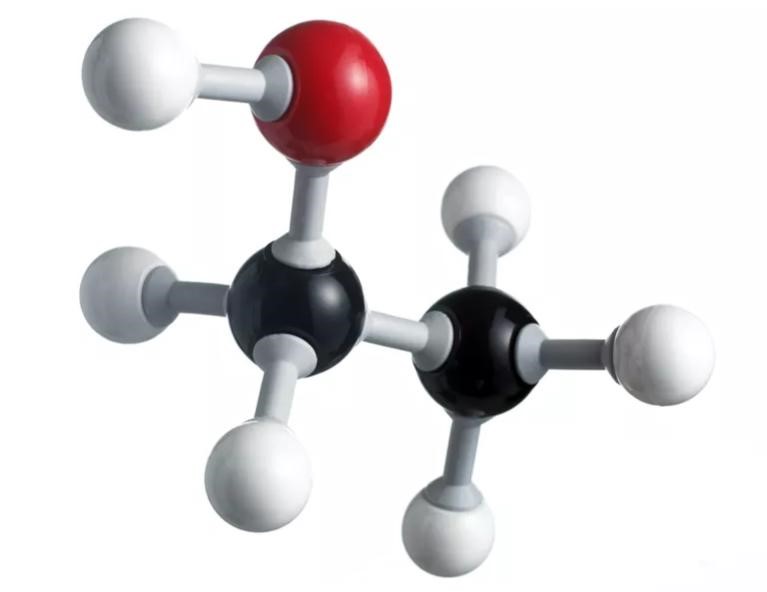

Ethanol is ethyl alcohol, sometimes a.k.a grain alcohol. It’s found in a variety of functional ingredients, including vanilla essence, lubricants, and washing goods. It is often used to make fragrances, culinary dyes, and flavorings, and lavender oil for a distillation process.

Nutrition ethanol has been proven to be appropriate for living thing use and ingestion, which cannot achieve from other alcohols. It is the 2nd most often used solvent, following water. It is now the least harmful alcohol, allowing some of the most commonly employed solvents in commodities.

With all of the abovementioned properties, it’s no wonder that ethanol is the most extensively utilized chemical in the marijuana market.

Ethanol can indeed be made by hydrating ethylene. Among the ethanol uses is that it is a sustainable power resource. It’s made of plant matter. Maize is the most common source of ethanol, but byproducts include wheat, sugar cane, tubers, malt, and cereal sorghum.

If processed carefully and purified to eradicate all soluble impurities in the resulting cannabis strain, ethanol in its especially could be a safe and convenient extraction process. Extraction has long been a necessary aspect of the industry in a variety of businesses, including natural ingredients, agricultural derivatives, and marijuana extracts. Extraction can be done with some compounds, notably hydrocarbons, Carbon dioxide, and ethanol, each of which has its own set of pros and cons.

How’s the Process Involving Ethanol for CBD Extraction?

Ethanol extraction involves combining ethanol with hemp to be separated as a reagent. The ethanol extracts the necessary marijuana chemicals (CBD and other cannabinoids, based on the organic matter) botanical extracts like lipids, oils, phytochemicals, and other elements from the organic material.

Ethanol extraction equipment generates pure liquids and extracts that are pure and hygienic. With the help of the oil refining devices, you’ll be capable of producing high lubricants as you’ve never before. Mixtures of flavours, fragrances, and therapeutic uses may now be made since you can dream of them. When it refers to our plants’ oil extraction equipment, we’ve already handled of the tricky bit.

CBD oil is extracted from cannabis plant products. There are a variety of methods for extracting oil from the herb and generating CBD oil. Because there is no waste after extraction, the solvent is considered a cleaner, purer kind of extraction.

The Following Is a Hypothetical Ethanol Extraction Method (Cold Temperature Ethanol Extraction Process Flow)

- Chilling: Use the DC-40 Precise Cooler to chill ethanol solutions to eliminate necessity post-extraction processes.

- Extraction: Using CUP Type sealed manual sedimentation, immerse and spin the feedstock in cooled ethanol solvent to separate them.

- Granular Filtration: Extract biosorbents and colloidal solids.

- Solvent Evaporation: Using a Falling Film Evaporator, eliminate ethanol from the formed waste.

- Decarboxylation: High-temperature crude ‘oxidised’ cannabis compounds (such as (the Cannabidiol, and CBGA) to remove the carboxylic chain in the form of Carbon dioxide and make these to their more readily ingested variants (like THC, CBD, and CBG).

- Distillate: Using Rolling Screen Filtration, extract the refined THC, CBD, CBG, or even other desired compounds from the crude oil.

- Chromatography: This will be employed for spectrum evaluation.

The extracted oil must be distilled after extraction to identify the different constituents (CBD being one of them). It is indeed important to note that removing ethanol from CBD oil even without a screen is incredibly difficult, lowering the strength and integrity of the resulting CBD oil.

The unusual creation of terpenes, which are water-soluble and hence fully functional — that is, the human body — is usually the main advantage of ethanol extracts.

As a result, combining the THCa or CBDa that occurs naturally in fresh marijuana with ethanol results in Tetrahydrocannabinol or Cannabidiol that would be inserted into the bloodstream.

What Kind of Ethyl Alcohol Is Utilized in The Procedure?

Slightly elevated solvents (190 and 200) are commonly utilized in the industrial ethanol extraction process.

How Does Ethanol Extraction Function?

The first thing that is important for producers harvesting marijuana with ethanol is either to function at relatively warmer conditions.

When using warm ethanol, the Steam distillation method will be utilized to boil, distill, and heat the ethanol. The floral matter will next be steeped in ethanol, represent only a small amount of leftover. Another of the key disadvantages of this method is that it is for small manufacturing.

In most cases, producers will opt for ethanol that is either ambient temperatures. The proportion of photosynthetic colors and hydrocarbons in the product is considerably minimized using this. At about the equal period, there is a great refinement.

Pros:

So, why are some industries using ethanol to generate marijuana and cannabidiol extracts? In the essence, it really is the most direct path to a fantastic end product. Using Ethanol, the retention constraints are far more permissive, enabling the facilities to store more stash while satisfying lower standards, enabling the customer to harvest enormous amounts of cannabis simultaneously.

However, there are advantages to cannabis ethanol extract, including:

Ethanol Extraction Is Remarkably Cost-effective:

Considering the excellent purity of its output. When compared to alternative solutions, it is usually connected with a much lesser initial investment (in terms of labor and equipment).

Easy and Flawless Ethanol Extracts:

Ethanol extraction, when implemented right, may obviate necessity dewaxing or remain in the environment. Regarding full-spectrum cannabis extracts and infusions, this is an excellent choice.

It is a Perfect Extricate:

Whenever ethanol is used in extraction, the result is an oil that is 99 percent purified. Ethanol absorbs (most) organic material, chlorophyll, hydrocarbons, and the since it dissolves easily. The final outcome is both a biological and composition that captures the plant’s inherent qualities and the smell which is unpleasant will be removed from excessive plant residues.

Safety:

Ethanol is classified as a “GRAS” (Generally Recognized as Safe) chemical by the Food and Drug Administration. This indicates that it is suitable for oral ingestion, which explains why it is found in several snacks.

Energy:

Ethanol has 75- 80 % of the energy of fuel in every barrel. It shows that any other machine can’t achieve this very same efficiency per tank. The idea that they are less expensive to manufacture offsets this statistic. They cover a lot more ground.

Versatile:

Based on the target use of a certain product, it can be used in a variety of ways. You may also evaporate off the hydrocarbons, providing you with such a strong and odorless oil that’s perfect for consumables and potions.

Cons:

Because ethanol is indeed a polar molecule, it will attract additional solubilized vegetative elements like chlorophyll.

- Because ethanol has significantly different boiling points than N – butanol or some other chemical composition is longer and far more difficult.

- Because ethanol’s range of products is restricted, commodities like shards or “sauce” are practically unlikely to achieve.

- Post-processing for ethanol extracts is more time-consuming than for hydrocarbon retrieval, and it comprises a variety of refining.

With something like a simple ethanol extraction device, one can handle massive amounts of cannabis extracts every day. The important part is bioavailability, whenever it relates to CBD oil. Oil-soluble chemicals are hard to absorb and must be dissolved by our body’s processes and chemicals, its pure & effectiveness.

Finally, CBD oil produced with ethanol is 100 % organic ethanol extract. Many health-conscious individuals will be delighted to hear this.